We are aware that engine downtime is expensive in terms of money and reputation. Flywheel Housing Supplier is a critical choice for technicians and OEMs seeking durability and precise alignment. We are interested in durable materials, small tolerances, and service that ensure vehicles and machinery that are running with minimal disruption.

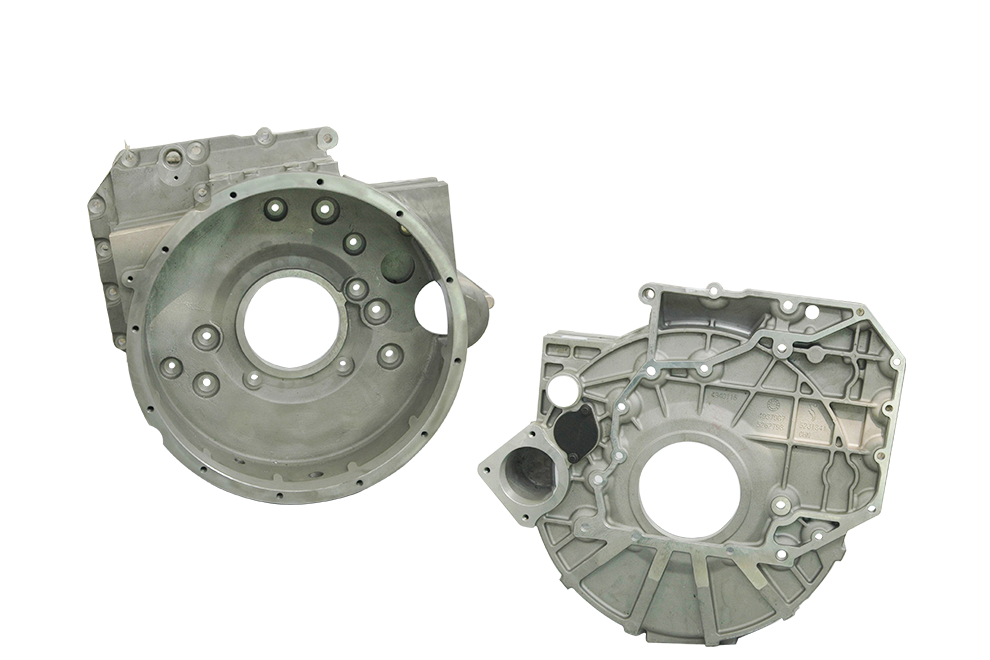

Our flywheel housings are of aluminum alloy and of cast iron. The units are machined to a tight tolerance so as to fit your engine block and transmission perfectly. It has features such as consolidated mounting boss holes, vibration damping ribs, and service access holes to the starter and the clutch. We provide custom bore size and bolt-pattern to a large variety of engines.

Why Quality Matters

Misalignment, noise, and increased wear are the effects of poor housing. Selection of the appropriate supplier enhances the efficiency in transfer of power as well as minimizing the maintenance cycles.

Well housings can also aid in the cooling of heat and reduce vibration to increase the life of components.Many partners choose this Flywheel Housing Supplier for dependable quality and traceable testing.

How We Support Customers

To confirm the fit, we provide technical drawings, material certificates and CNC prototypes. We have installation notes and torque suggestions on our engineers. On quality clientele we also have batch inspection reports and finishing options.

Applications and Industries

We are a trusted Flywheel Housing Supplier with consistent delivery. Automobile repair shops, heavy equipment fleets, marine engines, and aerospace support components are some of the clients of flywheel housings. They safeguard moving parts, maintain proper alignment of the engine to the gearbox and allow access to service regularly.

The process begins with the selection of material and continues with pattern designing, casting and precision machining. Every house is subjected to balance tests and stress tests. Finally, dimensional inspection and surface finish is included.

Why Choose Our Supply Chain

When you work with our Flywheel Housing Supplier you get clear documentation and responsive technical help.

We deal with individual prototypes on large production volumes. Alternatives are altered patterns of bolts, check-up windows, and sensor fixing sites. Present engine model and bolt pattern to be given a fast feasibility check.

Case Study: Fleet Improvement

A regional fleet operator replaced aging parts and selected our housings to improve reliability. After fit trials and material upgrades the operator reported fewer clutch-related failures and smoother power delivery. As a result, downtime dropped and maintenance costs fell. Their maintenance manager praised the clarity of our test reports and the rapid support provided by our engineering team.

Selecting a reliable Flywheel Housing Supplier made the retrofit straightforward and measurable. Partnering with informed engineers ensured a seamless transition and clear metrics for success.

Value Proposition

Balancing between material strength and machining precision, we provide the parts that satisfy the service demands. We are interested in quantifiable gains: the reduction of the number of failures, the appearance of regular service intervals, the availability of the testing history. Deal with a mature supplier that would assist with drawings, tolerances and after sales services. As a Flywheel Housing Supplier keeps strict checkpoints during production.

Check mounting bolts, seals and alignment. Substitute housings with cracks, severe corrosion or distorted faces to avoid collateral damages. Proper installation and torque avoid early failures.

FAQ

Q: What is the choice of the appropriate housing?

A: Sharing engine model, type of transmission, and bolt pattern. Likely, samples or drawings match.

Q: Do you provide prototypes?

A: Yes. We make CNC prototypes to check their fit prior to full production.

Q: Which inspections are provided?

A: There are dimensional checks, hardness checks and balance reports.

Check It Today

Precision components must have a knowledgeable partner that is knowledgeable of thermal and mechanical interfaces. Cooperate with the professionals, who are able to specify tolerances and to approve samples fast.

Questions regarding parts, drawings, or technical issues may be addressed to syrontech at christian@syrontech.com or call +86-0710-3337878. Chat WhatsApp/WeChat: +86 13600188484. Send part drawings to obtain a quotation.